In-House Furniture Designer

Designed private label products for the CPO (Chief Product Officer).

00

problem

The objective was to increase profit margins, differentiate their in-store offering, and build stronger customer loyalty through exclusive, well-designed alternatives to international brands.

solution

As Lead Product Designer, I designed and developed over 40 product collections, working directly with C-suite executives to generate more than $800,000 in annual revenue.

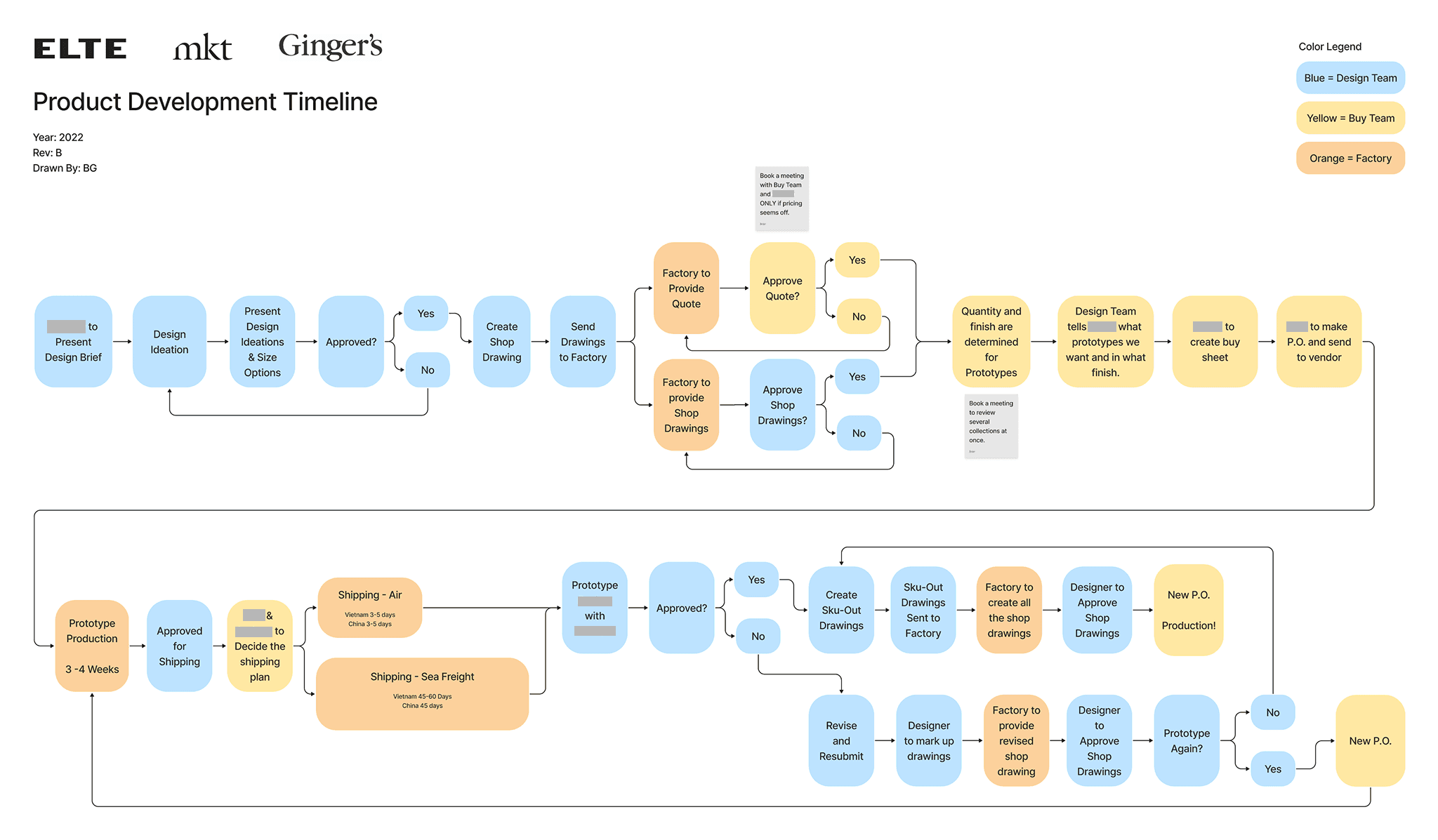

To support product development, I created an internal process flow chart mapping the full product life cycle.

As the second industrial designer brought on to scale the new white-label product line, my mandate was to design luxury furniture for retail. Leadership had identified an opportunity to allow customers to customize select products, but it quickly became evident that the organization lacked a formalized workflow to support it internally. In particular, there was no established process guiding the purchasing team through scenarios that required the design team to produce custom drawings, nor was there sufficient alignment with the sales team, who interfaced directly with clients. This created risk around expectations, timelines, and feasibility. Addressing these gaps required introducing clearer cross-functional processes and shared visibility into the constraints, lead times, and dependencies inherent in custom orders.

Quality Control

Working with overseas manufacturers required acute attention to detail. With high production cost, including labor, materials, and shipping, leaving little room for error, we often had just one shot to get it right. Construction drawings served as a contract between designer and manufacturer, while Zoom meetings and prototypes helped us fine-tune every detail to ensure accurate execution.

The Power of Details in Material Illusion

Designing in any medium means knowing how to use details to your advantage. The oak table shown below, for example, is made from veneered MDF, but it’s designed to appear as solid wood. End-grain veneer is used in a marquetry pattern that mimics traditional lap-joint joinery, creating the illusion of craftsmanship typically associated with solid timber.

01

02

03

see also